A Short History of the Flathead

A Short History and Evolution of the Flathead V8, and Making It Modern

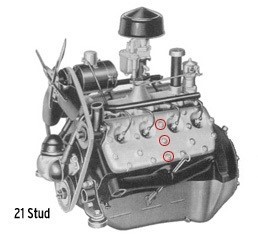

Back in 1932, Henry Ford introduced the 221 cubic inch Flathead engine producing 65 HP. And by 1935 HP was increased to 85 HP. Those engines were produced from 1932 to 1938 and were commonly known as “21 stud engines”, due to the head design using 21 head studs

In 1937 Ford introduced a 136 cubic inch variant, producing 45hp.

This engine was only in production from 1937 through 1938.

Although the engine was efficient, it was not very popular with the American public, who were now used to the 85 HP engine.

The 136 cubic inch engine was discontinued at the end of 1938 when the new Inline 6-cylinder Flathead was introduced.

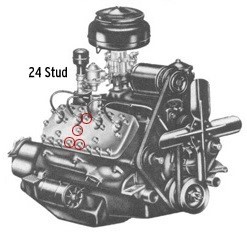

1938 saw the first major redesign of the 221 cubic inch Flathead engine, with the addition of more head studs, now totaling 24 studs. In 1939 the cubic inches were increased to 239 cubic inches and produced 95hp. These engines remained in production until 1948.

During World War II, 1943-1946, no engines were manufactured for the public due to the war effort (or at least, that I am aware of at the time of this writing).

The main characteristic of Flathead engines relating to Modern DriveLine, is the back of the engine block.

The 1932-1947 59A block casting utilized a ½ bell ring over the flywheel. The lower ½ ring was removable to provide access to remove and replace the Clutch, flywheel, and rear seal.

In 1948-1953 8BA/RT blocks no longer had the cast ½ ring.

Ford now used a single stamped metal bell ring for cars or a cast metal bell ring for trucks.

The intermediate ring with 3” depth, was used over the flywheel and clutch and used to attach transmission to the engine.

In 1948 to 1951, Ford produced the 337 cubic inch engine used in Lincoln cars and the F7 and F8 trucks.

Known as the 8EL in the Lincoln cars and 8EQ in heavy-duty trucks, these engines produced more horsepower and torque and weighed over 850 lbs.

These engines are physically larger and used 27 head studs and used a 12” clutch. Although this is a V8 flathead, very few parts from the 59A or 8BA engines are interchangeable.

Transmissions with Integral Bell Housings

From 1932 to 1951 all car and most light-duty trucks used transmissions with an integral bell housing that contained the clutch release mechanism. This mechanism consisted of a cross shaft mounted horizontally across the lower half of the bell and featured a vertically mounted clutch fork.

Ford utilized two different styles of cross shafts. Either a round shaft with a lever attached outside of the bell or a clevis with an extension rod and a lever closer to the frame.

1940-1951 Trucks With 4-Speed Spur Gear Transmission

During 1940 – 1952 Ford introduced a Heavy-duty 4-speed “Spur Gear” transmission. A spur gear transmission is a stand-alone unit, separate from the bell housing.

The clutch housing adapter known as the “Hogs Head” is used to mount the transmission behind the 3” intermediate ring and engine.

the hogshead adapter contained a vertically mounted cross shaft using a clevis with an extension rod and lever closer to the frame. The Hogs Head adapter has a cast number 59T-7006 on the inside of the housing.

From 1949 – 1953 Ford introduced the first versions of the modern bell housing where the clutch fork extended out of the driver’s side of the bell housing.

This was the start of the Y-Block bell style to transmission bolt patterns. These bells used one of two fork designs. One with pins on the inner diameter of the fork opening and one with raised pads facing forward.

Flywheels and Clutches

Ford used 9.5”, 10” Long, 11 Long, and 11” equidistant clutch pattern” flywheels and three-finger clutches depending on HP and use. Extra heavy-duty F7 and F8 vehicles used 12” clutches.

Moving Into The Future-Making It Modern

Why Modern Driveline?

MDL knows there are several different companies that supply conversion parts and good products based on the Chevy S10 T5 Non-World class transmission.

The Chevy S10 tail housing placed the shifter in a favorable position and was highly sought after for conversions. As the Chevy S10 transmission is no longer in production and parts are getting harder and harder to find.

Modern Driveline’s took the approach to “Make it Modern” by using the new Ford close-ratio T5z and TKO transmissions. Both the T5z and TKO are fully synchronized as compared to the S10 and offer greater strength well suited for the torque of Flathead engines.

In order to make the shifter location work with a T5z, Modern Driveline engineered a new replacement tail housing that moves the shifter to the front of the tail housing.

Known as the Front Shift tail housing, shifter locations can be as close as 9 ¾” from the back of the bell housing, all the way back to 15 ¼” with the use of offset shifters. The Modern Driveline Front Shift tail housing transmission mount location was moved back and does not interfere with the speedo cable, a common problem with the Chevy S10 tail housings.

The TKO transmission with the mid-shift kit can place the shifter 12.39” from the back of the bell housing. With a 2” forward offset the shifter can be moved to10.39” from the back of the bell housing.

Integrated Transmission Bell to Modern Transmission Conversions

To replace the single piece integral bell housing transmission, Modern Driveline engineered a new Adapter with either a round or clevis cross shaft design.

The Modern Driveline adapter can also be equipped with a modern hydraulic Tilton 6000 internal throughout bearing.

Modern Driveline also developed two Flathead flywheels and a line of modern diaphragm clutches to ensure a smooth conversion and proper clutch release.

1932-1948

1949-1953

Due to the design of modern diaphragm clutches, only 10” long pattern clutches fit the 59A engine and 8BA stamped or cast bell ring design. If OEM flywheel supports a 10” long pattern clutch, the OEM flywheel may be reused if serviceable with a Modern Driveline 10” long pattern clutch.

Truck Spur Gear Transmission to Modern Transmission Conversions

To replace a Truck Spur Gear 4-speed transmission, using the “Clutch Housing Adapter”, known as the “Hogs Head Adapter”.

Modern Driveline developed a “Hogs Head” adapter that mounts to the back of the Clutch Housing Adapter and accepts either a T5z or TKO Transmission.

For this conversion, a new MDL replacement fork and throughout bearing for use with a 10” long pattern clutch is provided with transmission conversion packages. If the OEM flywheel supports a 10” long pattern clutch, the OEM flywheel may be reused if serviceable in conjunction with a Modern Driveline 10” long pattern clutch.

Y-Block style bell to Modern Transmission Conversions

To convert from a Y-block style bell housing, 1949-1950 car bells had a cast #8BA 6392 and 1951 car bells had a cast #1BA 6392. And will use the Modern Driveline adapter.

From 1949 to 1951 Bells used a fork with pins.

If the pins are worn, Modern Driveline can provide replacement pins, MD-410-2101.

The original pins will need to be ground or machined off.

The replacement pins are welded in place.

Modern Driveline can provide this service for a fee, plus shipping.

Another fork variant was from 1952 to 1953. Bell housing with cast #AC-6392D used a fork with pads facing forward.

Note: 1953 Truck bell cast number TAAC-7505-A is a ‘one-year-only’ part and is not supported with a Modern Driveline adapter at this time.

Clutches

Modern Driveline developed diaphragm clutches that are well suited for use with our conversion packages. Modern Driveline can provide 10” Long, 11” Long, and 11” equidistant pattern versions for use with the 1 1/16” diameter T5z input shaft or the 1 1/8” diameter TKO input shaft. Modern Driveline diaphragm clutches are all handmade in-house and tested for proper release rates.

For all 59A or 8BA/RT engines with the 3” intermediate ring, the 10” Long pattern diaphragm clutch is used. If the OEM flywheel supports the 10” long pattern clutch, it may be reused and will require resurfacing. For all other patterns, a replacement flywheel will be provided.

For Y-Block style bell housings flywheels, all pattern clutches except the 9.5” can be provided. If the flywheel is not serviceable, the Modern Driveline flywheel with the 10” long pattern clutch can be provided.

Note: The 9.5” clutches are not available due to the lack of parts.

If in doubt as to the clutch pattern, a flywheel ID chart can be sent verification.

Modern Driveline Flat Head Conversion Kits

All Modern Driveline packages are custom-tailored to fit your needs based on the vehicle configuration, horsepower, use, and personal preferences. The following is a list of parts that can be provided to make your Flat Head Modern.

This process starts with an interview where we ask pertinent questions to build your package. When questions can’t be answered, we ask for pictures to be sent to us directly. The old adage “A picture is worth a thousand words” goes a long way to ensure you get what you need the first time.

Modern Driveline works with each customer to build a conversion kit that is right for their project.

We start with an interview and ask discovery questions:

- A) Year, make, and model of the car or truck?

- B) Year of the engine? (59A or 8BA, 8RT)

- C) Transmission type? (integral bell, Hogs Head, Y-block bell (bell cast #), or Quick Time bell housing.

- D) Clutch release? (round or clevis cross shaft, or fork). If fork, bell information is helpful.

The answers to the above questions will determine how to adapt a new T5z or TKO transmission. - E) Flywheel clutch pattern. 10”, 11” Long or Equidistant?

- F) Type of clutch release to be used (mechanical or hydraulic) – hydraulic clutch release is truly a modern upgrade and is easy to install. Floor access yes or no?

- G) How will the vehicle be used? (street or strip, road course pro tour) – this is for proper clutch

selection.

- H) Where should the shifter be located – in most cases, we already know.

- I) Is the vehicle equipped with a torque tube – if yes, it must be converted to an open driveshaft/axle.

Modern Driveline will provide you with a complete transmission conversion package:

– Transmission (T5z FS/F or TKO midshaft

– Back of block adaption or Hogs Head adapter or bell adapter

– Bell if required

– Flywheel

– FW bolts

– Fork pins, if needed

– Clutch, mechanical or hydraulic

– Pressure plate bolts

– Clutch, Mechanical or hydraulic

– Clutch fork as required

– T/O bearing for Mechanical release

– Hydraulic master and T/O if requested

– Shifter lever

– Shifter ball

– Shifter boot

– Oil (3 quarts)

– Mechanical Speedo or electronic hookup

– Speedo gear and clip

– Tail shaft yoke or custom driveshaft

A cross member must be made to support this transmission.

References:

Wikipedia, Ford Tech manuals, Van Pelt

Please log in to leave a comment.

No Comments Yet